Everything you need to know about tire tread depth

Updated on 17.07.2023

Ensuring your tires are safe and in good working condition should be a top priority for every vehicle owner. This involves periodically checking your tire tread depth. The simplest way to do this is through a visual inspection. Look for areas that look worn or have uneven tread wear. In addition to visual inspections, there are several methods to measure tire tread depth, one of the most common being the penny test.

What is the minimum safe and legal tread depth?

The minimum safe tread depth is typically considered to be 2/32 or 1/16 of an inch. This is the minimum legal tread depth in most states, and it is the point at which the tire's ability to provide adequate traction is compromised. It is important to note that this minimum safe tread depth is only recommended for temporary use, and it is best to replace your tires well before they reach this point.

While there are no federal laws specifically dealing with tread depth, 42 states and Canada have regulations in place, with a minimum legal tread depth of 2/32 of an inch. Two other states, including California, have a minimum of 1/32 of an inch. However, six states have no standards. Since 1968, federal law has required that a wear bar be molded across all tires, indicating when tires have worn down to the legal limit of 2/32 of an inch. All tires sold and manufactured in North America are required to have these wear bars, which become visible when the tires have worn out and should be replaced immediately. It is dangerous to drive on tires with tread depth less than 2/32 of an inch and could result in a ticket in some states.

What is the tread depth on a new tire?

The tread depth on a new tire is usually around 10/32 of an inch or 8mm. This varies depending on the manufacturer and the type of tire, but it is generally around this depth.

All-terrain and mud tires have much bigger tread, it can be up to 1 or even 1.5 inches.

How to Check Tire Tread Depth

To check your tire tread depth, there are several methods and instruments that can be used:

The penny test

The penny test involves inserting a penny into the tire’s tread with Lincoln’s head facing down. If you can see the top of Abe’s head, this indicates that your tread depth is below 2/32 of an inch, suggesting it’s time to replace your tires. The U.S. Department of Transportation recommends replacing tires when they reach the end of their life, which usually is when the tread depth is at this minimum legal limit.

The quarter test is another way to check tread depth. Place a quarter into the tread groove. If the top of Washington's head is visible, the tread is at least 4/32 inches deep.

Tire tread depth gauge

Another method is to use a tire tread depth gauge, which is a tool specifically designed to measure tread depth. This device can be purchased from a local auto parts store or a tire shop. The gauge is inserted into the tread of the tire, providing a vertical measurement between the top of the tread and the bottom of the tire's grooves. These gauges are quite accurate and provide measurements in 32nds of an inch, the standard unit of measurement for tread depth in the U.S. This allows you to check the remaining tread depth and determine whether your tires are nearing the end of their lifespan.

Vernier caliper

A caliper is a very accurate instrument that many people have in their garage or at home. Not everyone knows that it has a depth rod, just for measuring the depth of something. To measure the depth of a tire protector, you need to set the caliper to zero, lean it against the tire at a 90-degree angle, and extend the instrument until the depth rod touches the bottom of the tire groove.

Tread wear indicator bars

All modern tires come with built-in tread wear indicator bars, commonly known as "wear bars". These are raised sections that run in-between the tread ribs. They become flush with the tire's tread pattern when the tread depth reaches 2/32 of an inch, signaling it’s time for new tires.

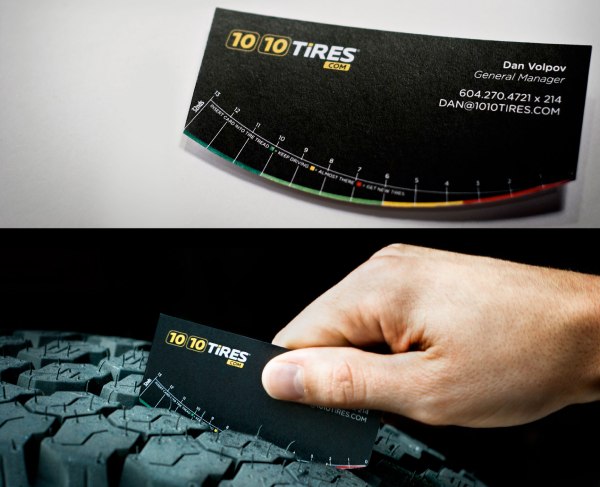

Business cards

No kidding, there is just such a way! Some tire manufacturers or retailers produce business cards or other printed marketing products with wear indicators on them.

What is good tire tread depth?

So, we have determined what is the minimum depth of tire tread, so as not to break the law and at least somehow stay on the road. Now we need to talk about what tread depth is good enough for normal driving. Let's look at the tests from manufacturers and independent organizations.

Adac tests and recommendations

According to ADAC (Germany's largest automobile association) tests, the minimum legal tread depth provides only minimal safety. To ensure optimal safety in wet, snowy, or slushy conditions, summer tires should have a tread depth of at least 3mm (~ 4/32 inches), and winter or all-season tires should have a tread depth of at least 4mm (5/32 inches).

In some European countries, tires with less than 4mm of tread depth are classified as summer tires, and may not be used on certain roads during the winter, such as in Austria.

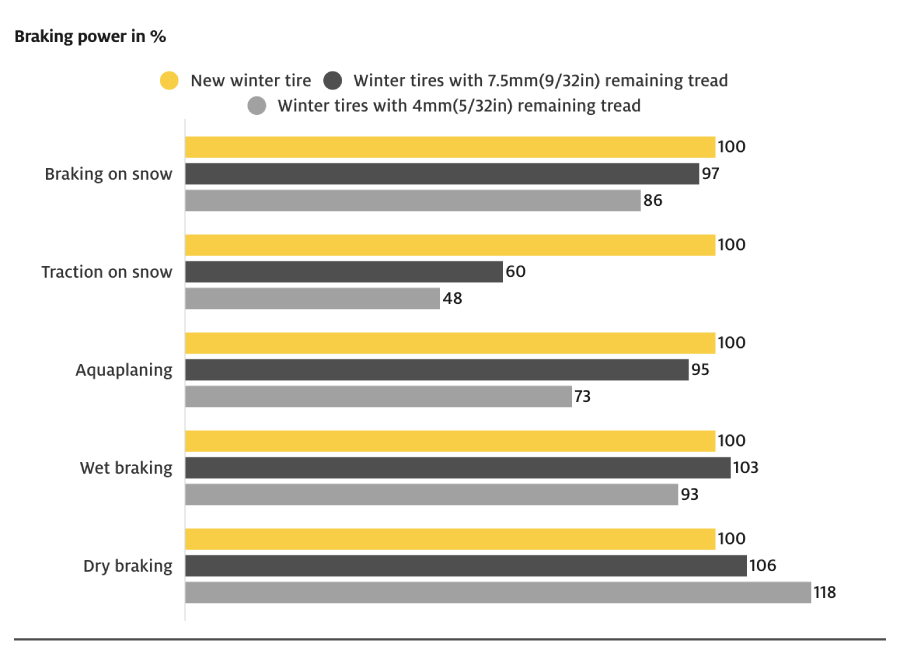

To evaluate the impact of low tread depth on tire performance, ADAC tested winter tires that rely heavily on their tread's grip in snowy, wet, and slippery conditions. The test used 185/60 R14 tires and evaluated driving and braking performance on dry, wet, and snow-covered roads at three different tread depths: 8mm (new condition), 7.5mm, and 4mm (recommended replacement point).

Here are the results chart:

On snow

The contrast between new and worn tires is most apparent on snow. Even a tire with 4mm of tread causes a 10.5 feet longer braking distance than a new tire at 18.6 mph. The difference in traction is even more pronounced when starting or driving on inclines, as the depth of the sipes - grooves in the tire - plays a crucial role in gripping loose snow. It is clear that a tire with a 7.5mm remaining tread depth can only exert 60% of the traction force compared to a new tire with a slightly deeper 0.5mm profile, and a tire with only 4mm of tread can only manage half as much.

Wet conditions

When driving in wet conditions, it is crucial for a tire's tread to effectively channel and displace water using its longitudinal grooves and sipes, to avoid hydroplaning. It's clear that a tire worn down to 4mm will start to aquaplaning at 40mph, while a new tire will only start aquaplaning at 54mph.

During wet braking, the rubber compound is the most critical factor. In this scenario, the worn tire also performs worse with a 7% longer braking distance (measured at 50mph).

Dry road

As you can see on the chart, on winter tires, braking distances actually shorten as the tread wears down. The reason for this is that the flatter tread blocks deform less while braking, resulting in more rubber making contact with the road surface.

Continental recommendations

Tire manufacturer Continental conducted its braking tests on wet and snowy roads. The tests were:

195/65 R15 91V, ContiPremiumContact 2, VW Golf IV, braking on wet, from 50mph to 0 mph

and

205/55 R16 91H, ContiWinterContact TS 830, VW Golf V, braking on snow, from 30mph to 0 mph.

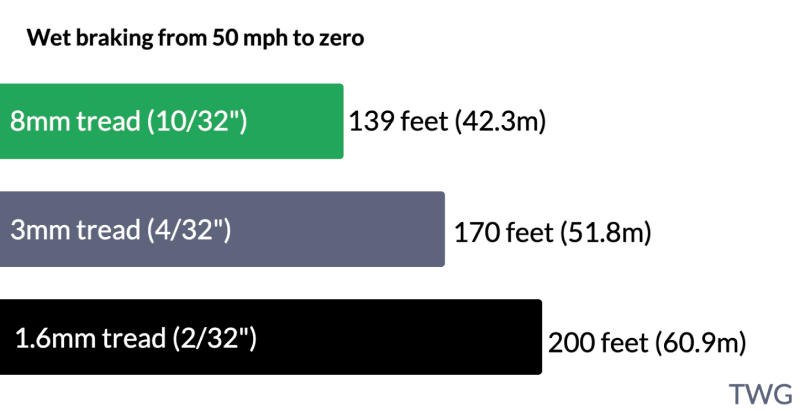

The results of the wet braking test are shown in the chart below.

We see that the new tires helped the car stop at 139 feet, with a 4/32 inch(3mm) tread depth remaining at 170 feet, and with the minimum recommended tread depth of 2/32 inch(1.6mm), the car was able to stop from 80 mph in 200 feet. That is, the difference between new and worn tires was 61 feet, which is about the same as three Chevy Suburbans.

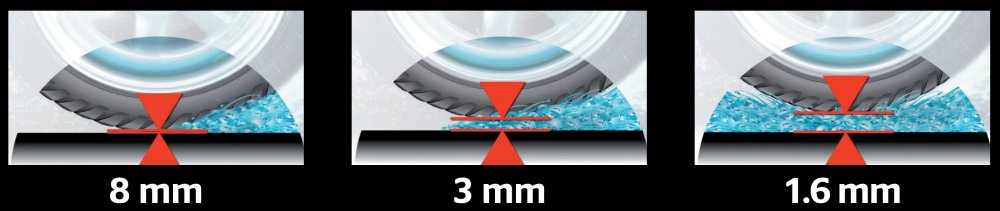

The big drop in performance of worn tires in the wet is mainly due to aquaplaning. When a wheel drives into the water at speed, the tire's worn grooves have no time to remove water from the contact patch with the road. And the more the tires are worn, the greater the layer of water between the tire and the road.

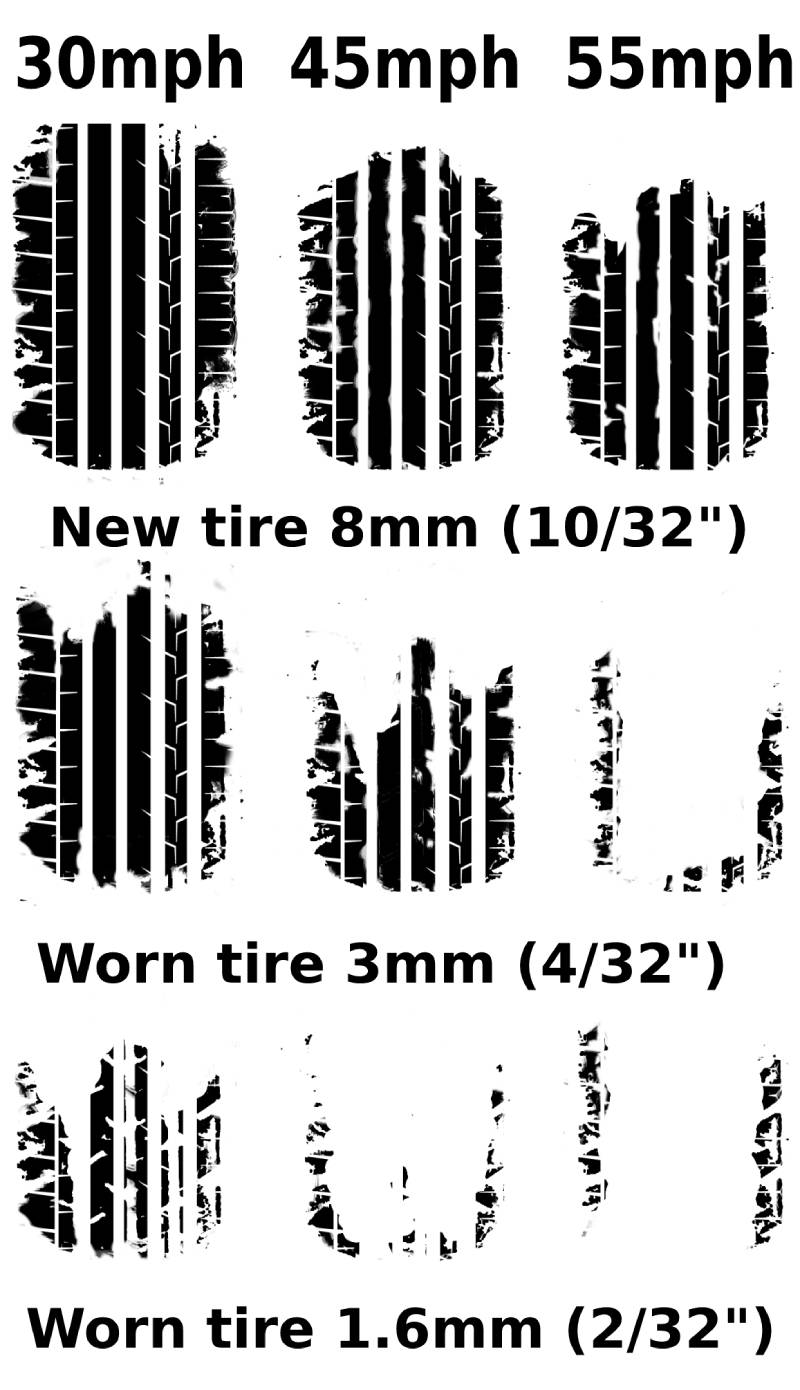

Here you can see how the contact patch of new and worn tires looks on the wet road at different speeds.

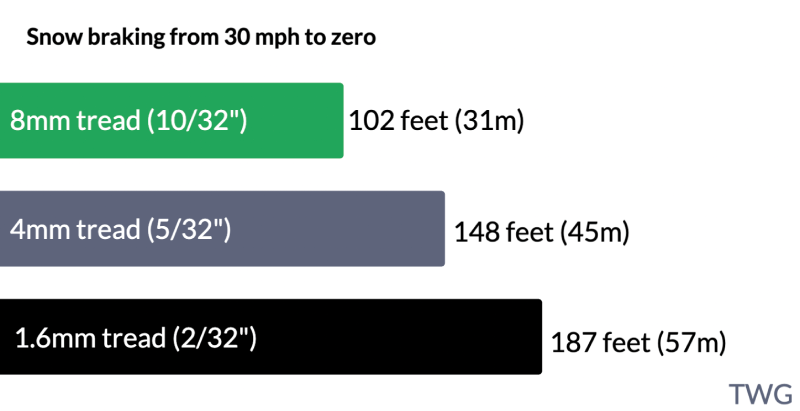

The results of the snow braking test are shown in the chart below.

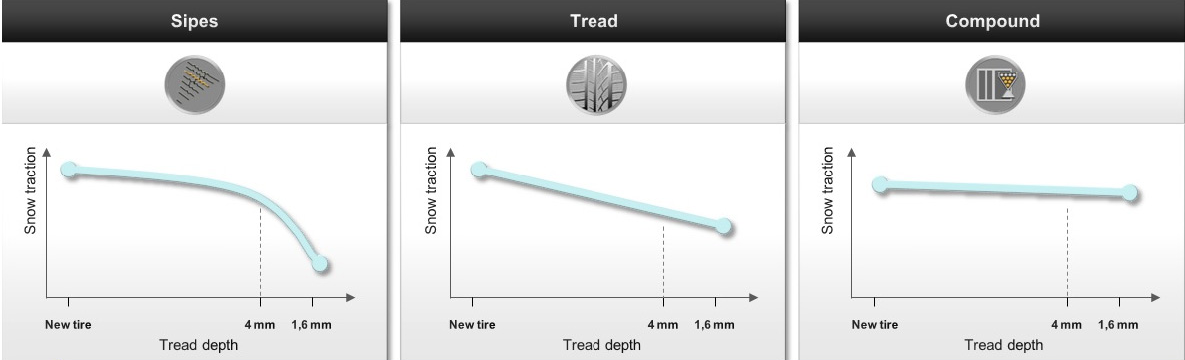

We see that the new tires helped the car stop at 102 feet, with a 5/32 inch(4mm) tread depth remaining at 148 feet, and with the minimum recommended tread depth of 2/32 inch(1.6mm), the car was able to stop from 30 mph in 187 feet. That is, the difference between new and worn tires was 61 feet, which is roughly equal to more than four Chevy Suburbans. For winter tires, tread depth is especially important because the winter tire pattern is equipped with special sipes - very thin slots whose task is to increase the softness of the tire blocks, thereby increasing the contact patch with the road. These sipes wear out rather quickly, and this leads to a loss of traction qualities. Here's a diagram of how the qualities of winter tires and their individual parts change depending on wear.

Maintaining Proper Tire Pressure and Tread Depth

Maintaining the correct tire pressure and tread depth is crucial not just for safety, but also for the overall performance of your vehicle. Tires with the right pressure and tread depth ensure optimal contact with the pavement, allowing your vehicle to grip the road better under various driving conditions.

Driving on tires with a worn tread or low tire pressure can increase your stopping distance in wet conditions, reduce your vehicle's handling ability, and increase the risk of tire failure. It's especially important to have deeper tread for winter tires, as they are designed to grip snow and ice, reducing the likelihood of hydroplaning.

Replacing Your Tires

If you measure your tread and find you have less tread left than the minimum recommended amount, it's a clear sign you need new tires for your vehicle. The type of tire you choose - whether winter tires, summer tires, or light truck tires - will depend on your specific driving needs and conditions. Be sure to consult with a tire shop or auto parts store to find the best tires for your circumstances.

Don't delay in replacing your tires if they show signs of excessive tire wear, as worn tires may compromise your safety on the road. Driving on tires that are at the end of their lifespan can also potentially lead to tire damage, negatively impact your vehicle's fuel efficiency, and even cause tire failure.

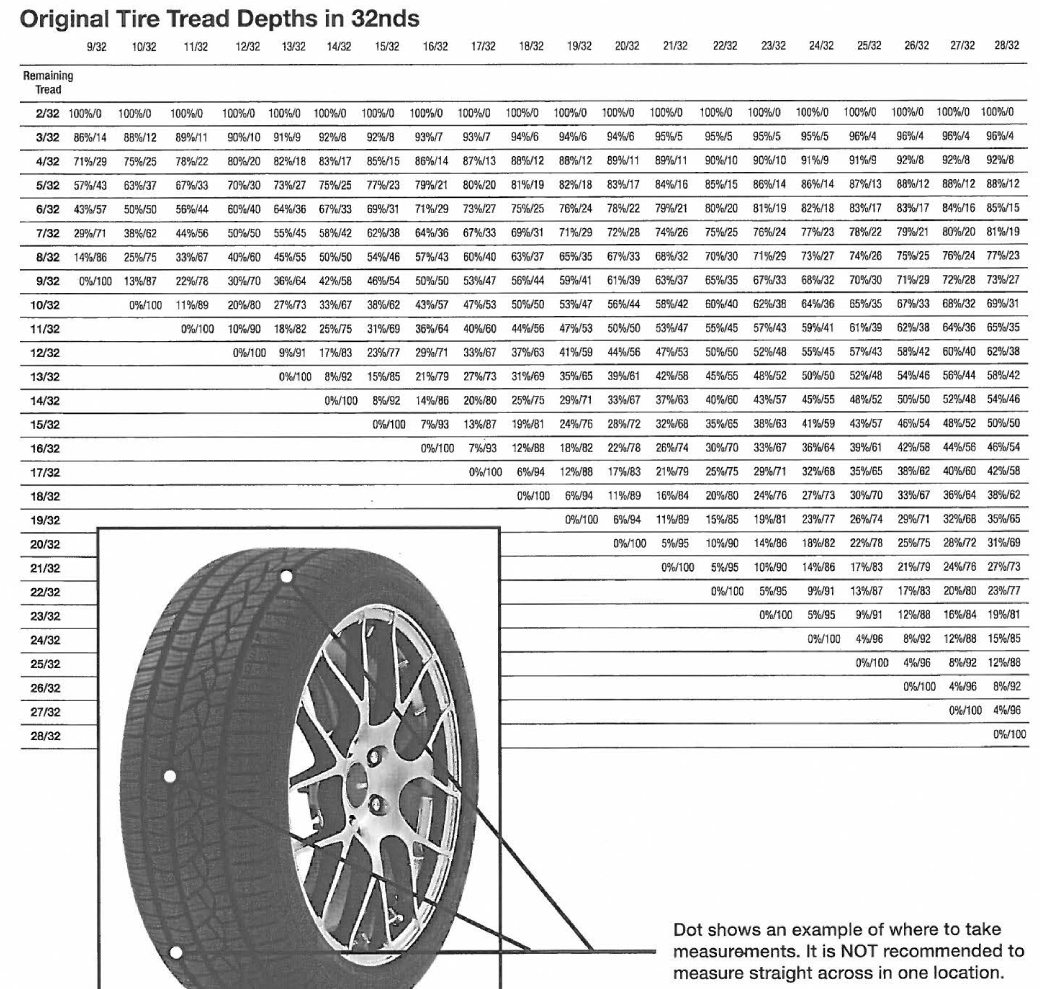

Tire tread depth conversion chart to the percentage of wear

Tire Tread Depth Conversion to 32nds

| Fraction /32"s | Inch | mm |

| 1/32" | 0.031 | 0.79 |

| 2/32" | 0.063 | 1.59 |

| 3/32" | 0.094 | 2.38 |

| 4/32" | 0.125 | 3.18 |

| 5/32" | 0.156 | 3.97 |

| 6/32" | 0.188 | 4.76 |

| 7/32" | 0.219 | 5.56 |

| 8/32" | 0.250 | 6.35 |

| 9/32" | 0.281 | 7.14 |

| 10/32" | 0.313 | 7.94 |

| 11/32" | 0.344 | 8.73 |

| 12/32" | 0.375 | 9.53 |

| 13/32" | 0.406 | 10.32 |

| 14/32" | 0.438 | 11.11 |

| 15/32" | 0.469 | 11.91 |

| 16/32" | 0.500 | 12.70 |

| 17/32" | 0.531 | 13.49 |

| 18/32" | 0.563 | 14.29 |

| 19/32" | 0.594 | 15.08 |

| 20/32" | 0.625 | 15.88 |

| 21/32" | 0.656 | 16.67 |

| 22/32" | 0.688 | 17.46 |

| 23/32" | 0.719 | 18.26 |

| 24/32" | 0.750 | 19.05 |

| 25/32" | 0.781 | 19.84 |

| 26/32" | 0.813 | 20.64 |

| 27/32" | 0.844 | 21.43 |

| 28/32" | 0.875 | 22.23 |

| 29/32" | 0.906 | 23.02 |

| 30/32" | 0.938 | 23.81 |

| 31/32" | 0.969 | 24.61 |

| 32/32" | 1.000 | 25.40 |

Conclusion

In conclusion, checking your tire tread depth is a crucial part of vehicle maintenance. By keeping an eye on your tire tread wear and knowing when it's time to replace your tires, you can ensure that your vehicle remains safe and performs optimally under all driving conditions.